product

FEATURES

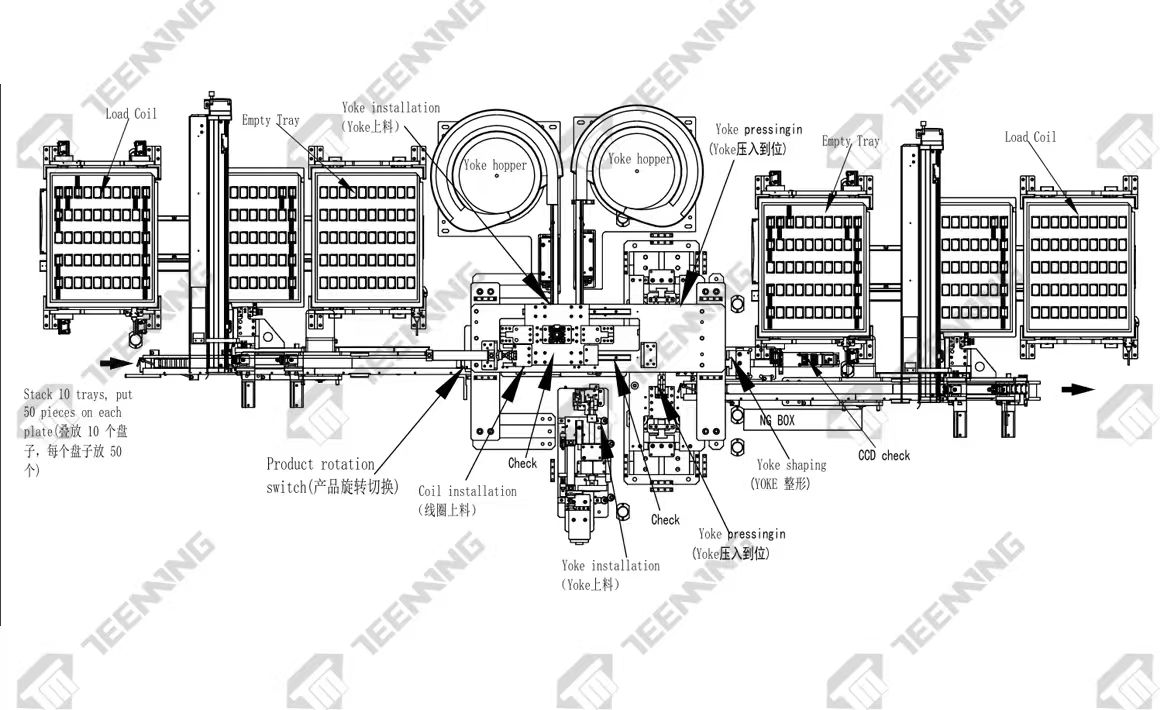

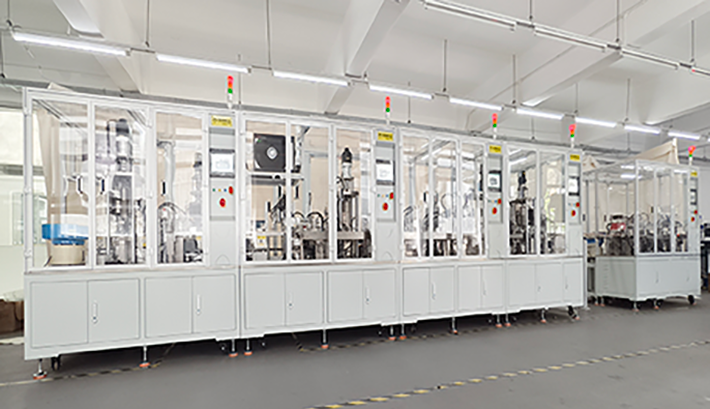

1.Batch-friendly: 10 stacked trays (50 yokes each) for large-scale production.

2.Full-process integration: Covers feeding, shaping, assembly, CCD inspection, and NG sorting.

3.Flexible adaptability: "Product rotation switch" for multi-model compatibility.

4.Automated & quality-controlled: Yoke hoppers for feeding, CCD inspection, and NG BOX for traceability.

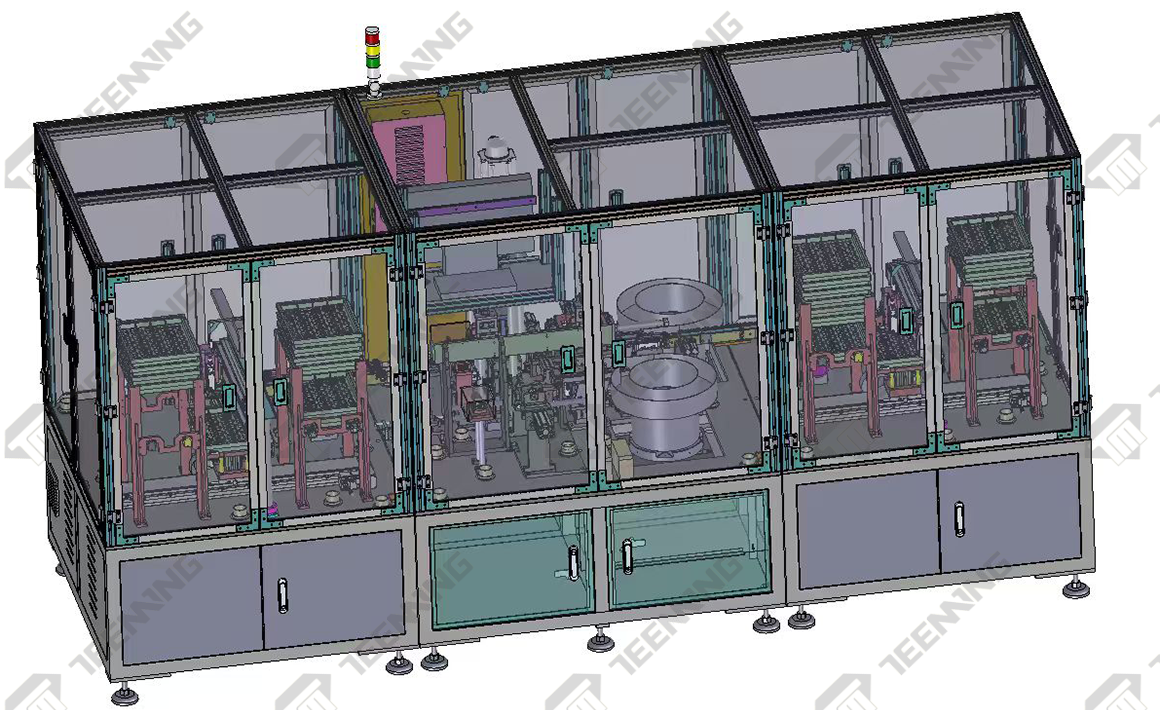

5.Equip with automatic safety door.

2.Full-process integration: Covers feeding, shaping, assembly, CCD inspection, and NG sorting.

3.Flexible adaptability: "Product rotation switch" for multi-model compatibility.

4.Automated & quality-controlled: Yoke hoppers for feeding, CCD inspection, and NG BOX for traceability.

5.Equip with automatic safety door.

PROCESS

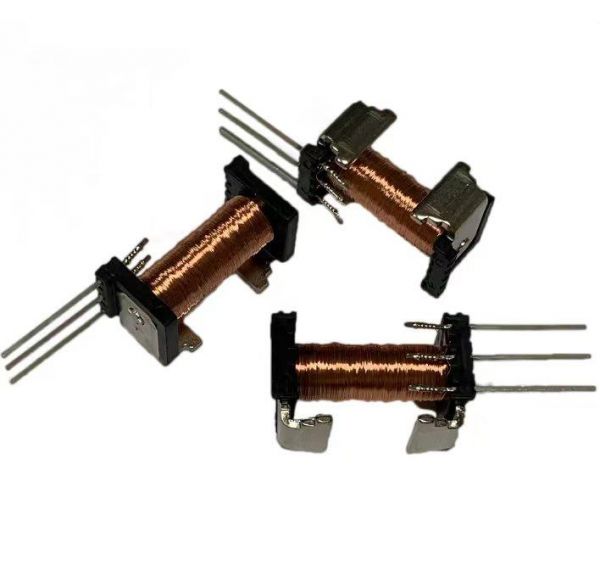

Coil tray (Each tray can hold 50 coils, and 10 trays can be stacked )

↓

Coil feeding

↓

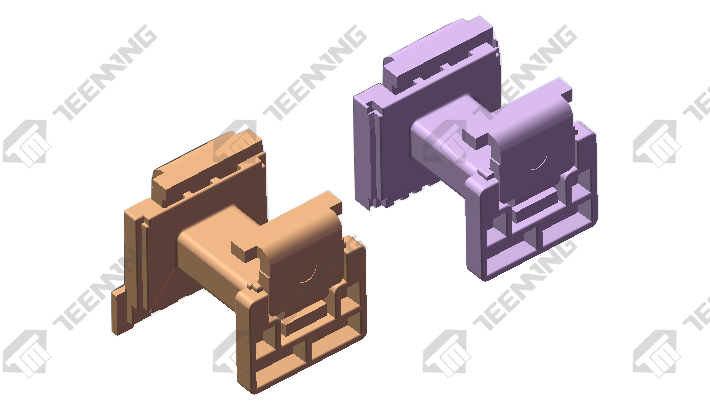

Yoke feeding

↓

Yoke pressing in place

↓

Yoke shaping

↓

CCD inspection (Yoke assembly spacing)

↓

NG product rejection

↓

Finished product tray arrangement

↓

Coil feeding

↓

Yoke feeding

↓

Yoke pressing in place

↓

Yoke shaping

↓

CCD inspection (Yoke assembly spacing)

↓

NG product rejection

↓

Finished product tray arrangement

SPECIFICATION

Machine Model:TM-T6138

| Power source | AC 220 50 HZ 1Phase |

| Machine dimension | 3800(L) x1260(w) x1870(H)mm |

| Weight | 1817KGS |

| Air pressure | 6KG/ cm2 |

| Cycle time | 3.6sec/ lpcs |

| Yoke type | L |

Option |

Bowl feeder |

| Safety cover | |

| Safety Light Curtain |