- WELDING MACHINE

- Toroidal Winding Machine

- ASSEMBLY

- CUSTOMISED AUTO LINE

- PIN INSERTING MACHINE

- AUTO COIL WINDING MACHINE

- AUTO WINDING & TAPING MACHINE

- MOTOR WINDING MACHINE

- SEMI-AUTO WINDING MACHINE

- TAPING MACHINE

- TENSIONER FOR COIL WINDING

- SOLDERING MACHINE

- PACKAGING MACHINE

- LAMINATION INSERTING MACHINE

- ALL

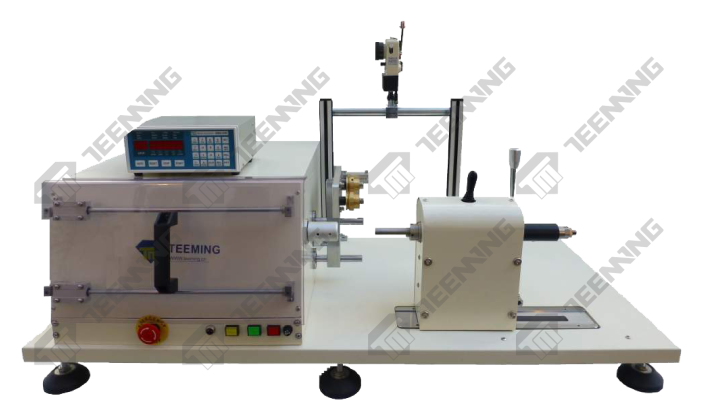

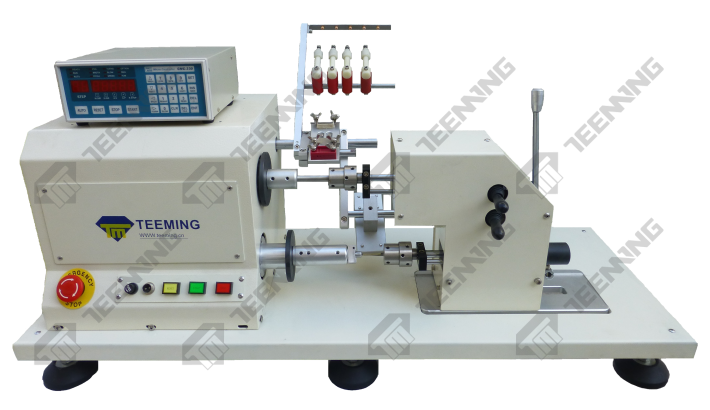

SEMI-AUTO WINDING MACHINE

Process - Semi-auto Winding Machine

1. Load the bobbin onto the spindle of the semi winding machine. Secure the bobbin in place to prevent any movement during the winding process. The tooling serves as the foundation for the wire coils.

2.Start the winding machine to initiate the winding process. The semi machine will rotate the bobbin and guide the wire onto it according to the specified parameters.

3.End winding, once the desired number of turns or layers is reached, secure the ending end of the wire to the bobbin.

4.Carefully remove the fully wound bobbin from the spindle. Take care to avoid any damage to the wound coils during the unloading process.