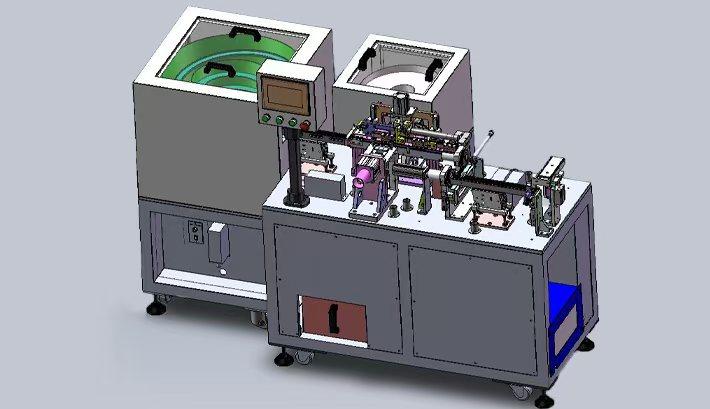

- AC servo motor

- Load coil by auto

- Automatic insert IDC

- Automatic wrap and cut with fake pin

- Automatic trace

- Automatic unloading

↓

Pre-insert terminal

↓

terminal into wound coil

↓

Check terminal

↓

Return finished coil to bobbin holder

| Control system | AC Servo Motor |

| Data storage | 2GB CF Card |

| Load bobbin Q'TY | 8 pcs |

| Load Bobbin distance | 40mm |

| Max. bobbin diagonal | 70mm |

| Production capacity | 8 Sec/1 PCS |

| Max. speed of slider | 3000 RPM |

| Spindle way accuracy | +/-0.02mm |

| Power Source | 1φ AC220V,50/60HZ |

| Consumed power | 4KW |

| Air pressure supply required | 5-6KGS/c㎡ |

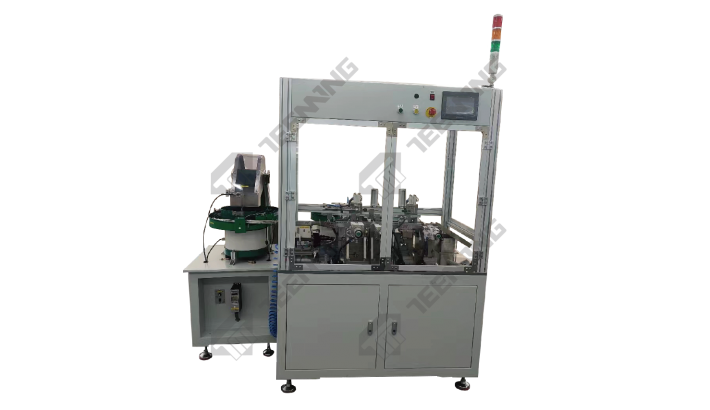

| Machine dimension | 2450(L)X1700(W)X1950(H) mm |

| Machine weight | 1400 kgs |

Related Products

AIP-28 AUTO PIN INSERTING MACHINE

(1) The body is inclined to 30 degrees, easy to feed and withdraw materials, and the vibration barrel for feeding materials is optional.

(2) large versatility, only need to replace special components, can change the type in a short time.

(3) Round PIN, corner PIN, flat PIN, are applicable.

(4) Up to 20 pins can be inserted at the same time.

(5) PIN length, groove position, easy to adjust.

(6) When the wire is used up or broken, it can automatically detect the stop.

(7) Outside the linear PIN press, it can also be bent PIN 0~90 degrees.

(8) Can be used with the production line according to the user's requirements and design