product

FEATURES

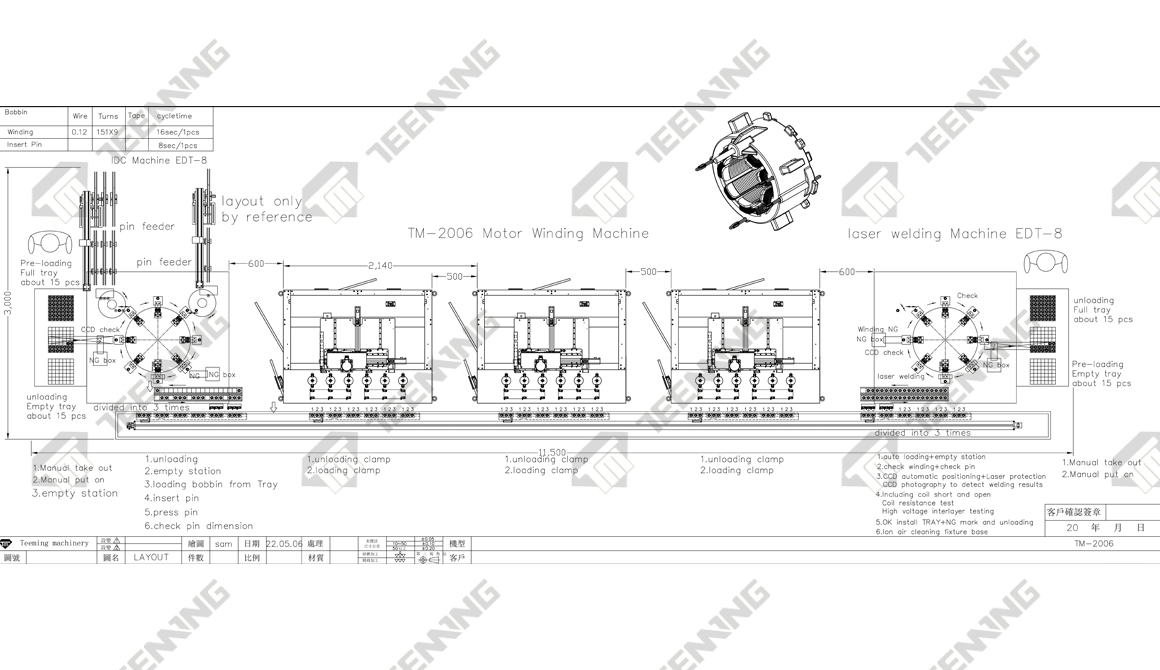

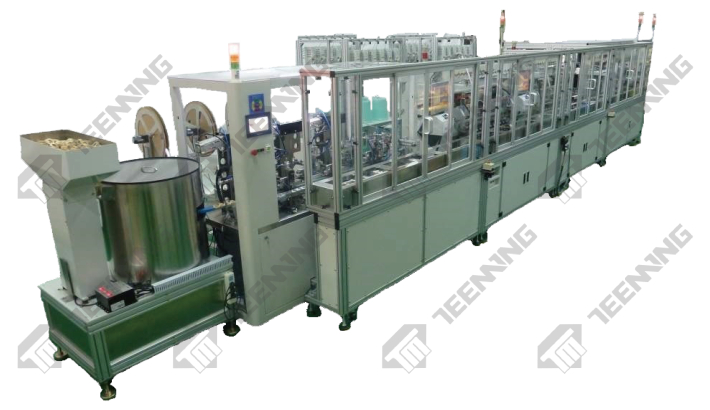

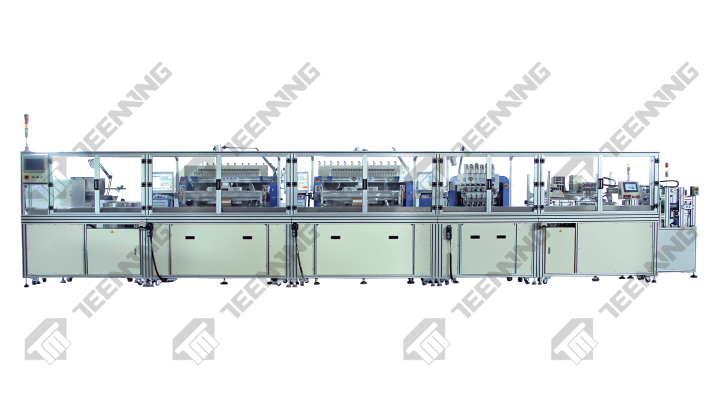

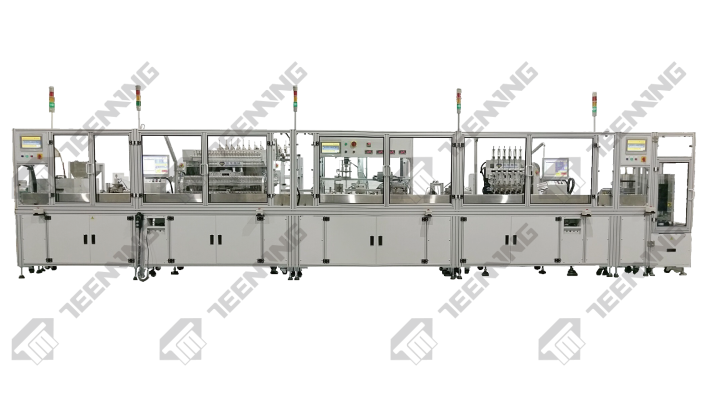

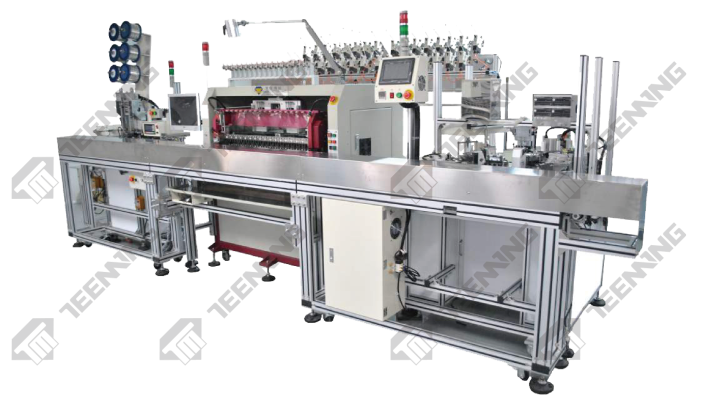

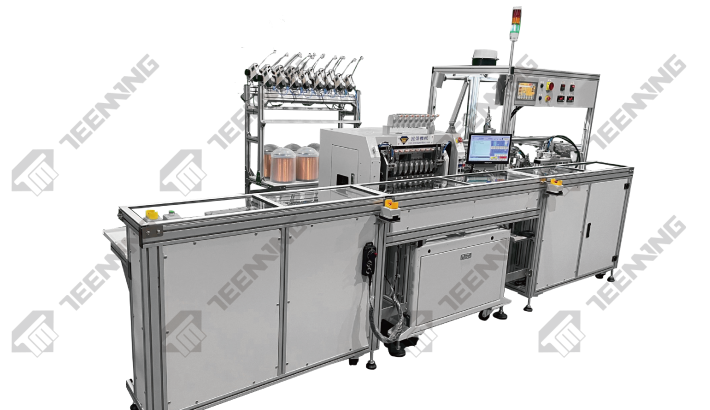

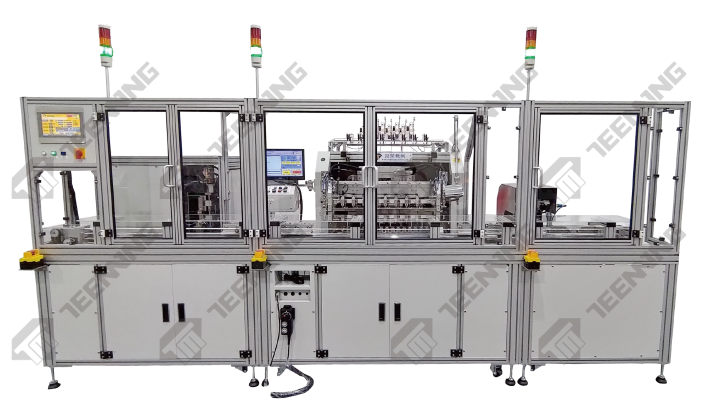

This line uses mechanical drive system, servo system and pneumatic system to realize automatic pin insertion, automatic wire winding, automatic welding, automatic detection, whole line automation, and improve the stator yield. The machine is easy to operate, high degree of automation, suitable for series motor, brushless DC motor, stepper motor stator.

1.Electronic tensioner, HMI controlled tension, multi-stage tension selection, with MES system connection

2.Machining parameters can be set and saved on the man-machine interface, and can be recalled at any time

3.ccd system for the whole process monitoring and identification, separation of nonconforming products for data analysis

4.Flexibility -function modularized structure design, to realize fast replacement of tooling, quick adapt to variants

1.Electronic tensioner, HMI controlled tension, multi-stage tension selection, with MES system connection

2.Machining parameters can be set and saved on the man-machine interface, and can be recalled at any time

3.ccd system for the whole process monitoring and identification, separation of nonconforming products for data analysis

4.Flexibility -function modularized structure design, to realize fast replacement of tooling, quick adapt to variants

PROCESS

Stator tray loading

↓

Pin inserting machine

↓

CCD check pin dimension

↓

Conveyor to winding machine

↓

Winding machine (six spindle) * 3

↓

Laser welding

↓

CCD check welding appearance

↓

Ohm test

↓

Tray unloading

↓

Pin inserting machine

↓

CCD check pin dimension

↓

Conveyor to winding machine

↓

Winding machine (six spindle) * 3

↓

Laser welding

↓

CCD check welding appearance

↓

Ohm test

↓

Tray unloading