product

TM-F3502 FLYER WINDING MACHINE

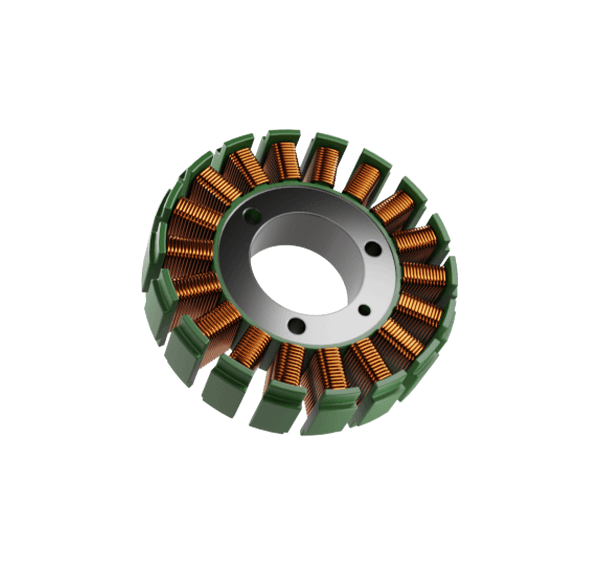

A motor winding machine used on stators is a specialized device designed to wind coils of wire onto the stator core of an electric motor. The stator is an essential component of an electric motor that remains stationary and provides the magnetic field necessary for the motor's operation.

The motor winding machine automates and streamlines the process of winding copper or aluminum wire around the stator core to create the stator windings. These windings are responsible for generating the electromagnetic fields required for the motor to function. Proper winding is crucial for the motor's performance, efficiency, and reliability.

Using a motor winding machine for stators, BLDC motor or core manufacturers can achieve consistent and precise winding of the stator coils, ensuring motor performance and reliability. These machines play a crucial role in the efficient and cost-effective production of electric motors used in various applications, from household appliances and industrial machinery to electric vehicles and renewable energy systems.

The motor winding machine automates and streamlines the process of winding copper or aluminum wire around the stator core to create the stator windings. These windings are responsible for generating the electromagnetic fields required for the motor to function. Proper winding is crucial for the motor's performance, efficiency, and reliability.

Using a motor winding machine for stators, BLDC motor or core manufacturers can achieve consistent and precise winding of the stator coils, ensuring motor performance and reliability. These machines play a crucial role in the efficient and cost-effective production of electric motors used in various applications, from household appliances and industrial machinery to electric vehicles and renewable energy systems.

FEATURES

- Accurate core wire positioning.

- High-speed flyer winding to reach maximum productivity.

- The flyer winding machine can set multi-angle by servo motor.

- This motor winding machine can perform perfect layer winding.

- Lower noise and lower fault rate.

- Winding speed can adjust according to the stack height.

- Customize jig and change it easily.

PROCESS

Load core on the fixture by hand or robotic

↓

Winding

↓

Automatic needle

↓

Winding

↓

Automatic needle

SPECIFICATION

| Wire size | 0.15~1.6mm |

| Product dimeter | 200mm Max. |

| Thickness | 10~50mm |

| Slot | 4~40 slot |

| Rotating speed | 10~3000RPM |

| Controller | Computer,Ethernet automatic control |

| Motor | AC servo motor (3 sets) |

| Winding motor | Servo motor 1 set |

| Aligning motor | Servo motor 1 set |

| Angle motor | Servo motor 1 set |

| Efficiency | 2/once |

| Power source | AC 220V 3 phase,50/60HZ |

| Machine dimension | 900(L) x 1700(W) x 1900(H)mm |

| Machine weight | 750 kg |