product

TM-1566 AUTO TAPING MACHINE

A coil taping machine is a specialized device designed for applying tape to various products or components, particularly coils and related items. The primary purpose of a coil taping machine is to provide protection, insulation, or reinforcement to the materials being taped. These machines are widely utilized in industries such as electronics, automotive, and aerospace.

The coil taping machine is equipped with mechanisms to hold and dispense the tape, ensuring precision and consistency. The tape is typically supplied from a roll or spool and is carefully guided to achieve accurate application. Additionally, the machine features a cutting mechanism that trims the tape at the end of each wrapping cycle, producing clean and precise edges.

In the electrical and electronics industries, coil taping machines are commonly used to apply insulating tape or film to electrical wires, cables, and electronic components. This provides critical electrical insulation and protects against moisture and other environmental factors. These machines are particularly valuable in applications requiring precise and uniform taping, such as transformer coils, motor windings, and other delicate electrical components.

Coil taping machines offer an efficient and reliable way to improve production speed, reduce labor costs, and ensure high-quality taping results. Their versatility and precision make them an essential tool for modern industrial processes, particularly in sectors requiring specialized coil and component handling.

The coil taping machine is equipped with mechanisms to hold and dispense the tape, ensuring precision and consistency. The tape is typically supplied from a roll or spool and is carefully guided to achieve accurate application. Additionally, the machine features a cutting mechanism that trims the tape at the end of each wrapping cycle, producing clean and precise edges.

In the electrical and electronics industries, coil taping machines are commonly used to apply insulating tape or film to electrical wires, cables, and electronic components. This provides critical electrical insulation and protects against moisture and other environmental factors. These machines are particularly valuable in applications requiring precise and uniform taping, such as transformer coils, motor windings, and other delicate electrical components.

Coil taping machines offer an efficient and reliable way to improve production speed, reduce labor costs, and ensure high-quality taping results. Their versatility and precision make them an essential tool for modern industrial processes, particularly in sectors requiring specialized coil and component handling.

FEATURES

- Customize jig and change it easy

- Automatic loading and unloading

- Automatic taping

- Automatic cut tape

- Adjust tape quickly

- Simple construction, easily control and convenient maintenance

PROCESS

Put coil to the fixture and flux by hand

↓

Turn

↓

Set tape turns and cut position

↓

Cut tape

↓

Unloading

↓

Turn

↓

Set tape turns and cut position

↓

Cut tape

↓

Unloading

SPECIFICATION

| Power source | AC 220V 60HZ |

| Machine dimension | 380(L)x620(W)x320(H)mm |

| Machine weight | 100KGS |

| Cycle time | 2 sec/pcs |

| Bobbin size | EI35-EI66 transformer |

Related Products

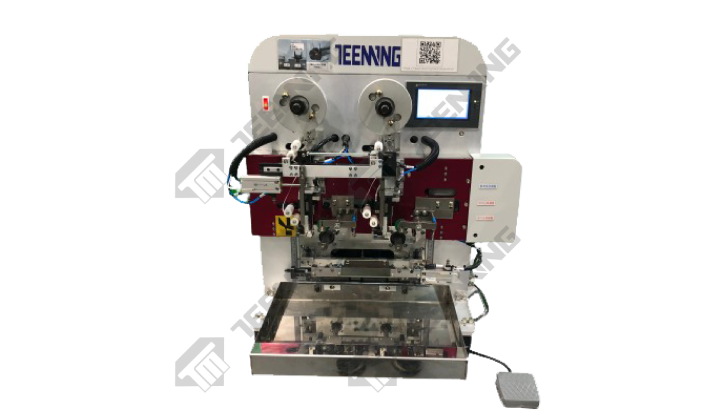

TM1602 2 SPINDLE TAPING MACHINE

Between 2 spindle pitch 160mm

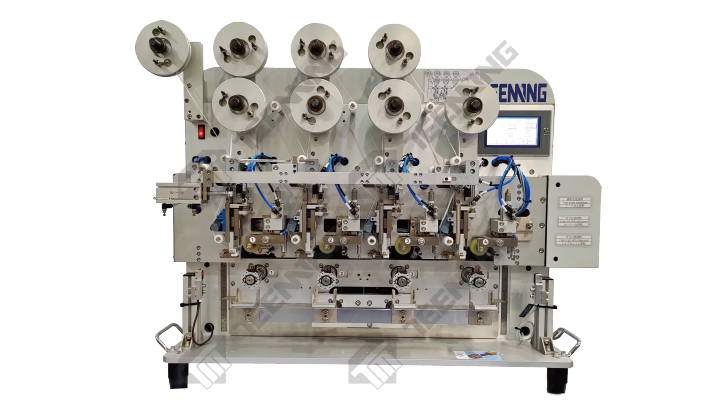

TM1604 4 SPINDLE TAPING MACHINE

Between 2 spindle pitch 160mm

TM-ETM-02 2 SPINDLE TAPING MACHINE

Between 2 spindle pitch 160mm

TM-3612-06-TP_6 SPINDLE AUTO TAPING

Between 2 spindle pitch 36mm

TM-1006-06-TP-6 SPINDLE AUTO TAPING

Between 2 spindle pitch 100mm

TM-5008-08-TP_8 SPINDLE AUTO TAPING

Between 2 spindle pitch 50mm

TM-3612-12-TP_12 SPINDLE AUTO TAPING

Between 2 spindle pitch 36mm