product

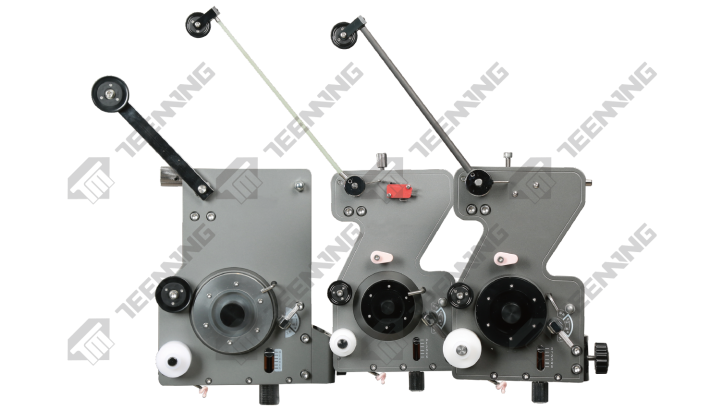

SERVO TENSIONER (800)

Used in various winding machine, motor winding machine, wire tensioners maintain the tension in wires to optimize their performance also can control tenioner when winding or wraping. Tensioners are typically adjustable, allowing fine-tune the tension level based on specific requirements. Some tensioners use springs or mechanical components to apply tension. The coil made by winding machine with tensioner, coil can use on relay,solenoid, transformer.

FEATURES

1.Preset tension segments: 8 tension stage can be preset through operations on the tensioner's localdisplay screen, or via RS485 communication.

2.Multiple multi - stage tension switching modes:

-10- based tension switching: The tensioner is equipped with 3- way switch quantities, and thepreset 8-stage tension can be controlled and switched through(PLC) 10..Pneumatic - driven tension switching: Connecting an air source enables 2-stage tension switchingby inflating and deflating the internal cylinder of the tensioner.The above two switching methods can be used in combination to achieve 16 -stage tension switching.

3.Multiple functional alarms: wire break alarm, fault alarm,tension upper/lower limit alarm functions.

4.RS485 networking communication enables integrated read - write control of all tensioners within thenetwork, operations such as program upgrades, and can also be connected to PLC via RS485 toachieve automated data collection and equipment integration.

5.Host -computer parameter adjustment: The tensioner is equipped with dedicated host -computersoftware for reading and writing internal parameters of the tensioner,adjusting its working statusand performance.

2.Multiple multi - stage tension switching modes:

-10- based tension switching: The tensioner is equipped with 3- way switch quantities, and thepreset 8-stage tension can be controlled and switched through(PLC) 10..Pneumatic - driven tension switching: Connecting an air source enables 2-stage tension switchingby inflating and deflating the internal cylinder of the tensioner.The above two switching methods can be used in combination to achieve 16 -stage tension switching.

3.Multiple functional alarms: wire break alarm, fault alarm,tension upper/lower limit alarm functions.

4.RS485 networking communication enables integrated read - write control of all tensioners within thenetwork, operations such as program upgrades, and can also be connected to PLC via RS485 toachieve automated data collection and equipment integration.

5.Host -computer parameter adjustment: The tensioner is equipped with dedicated host -computersoftware for reading and writing internal parameters of the tensioner,adjusting its working statusand performance.

SPECIFICATION

| Tension model | Tension Arm | Tension Spring | Tension Range(gf) | Wire Range | Woolfelt |

TMQ-800 |

SF2-200 | T2、T3、ST5 | 7~80 | 0.05~0.13 | φ25x6x4 |

| SF2-150 | T2、T3、ST5 | 10~100 | 0.06~0.14 | ||

| SF3-200 | ST10 | 70~330 | 0.12~0.25 | ||

| SF3-150 | ST10 | 100~440 | 0.14~0.29 | ||

| SF4-200 | ST-11 | 140~570 | 0.16~0.35 | ||

| SF4-150 | ST-11 | 200~800 | 0.20~0.40 |

Related Products

SERVO TENSIONER (2000/3000)

MULTI TENSION

DOUBLE-SERVO TENSIONER (800)

MULTI TENSION

DOUBLE-SERVO TENSIONER (2000)

MULTI TENSION

SPRING SERVO TENSIONER

CONTROL BY SERVO TENSIONER

SPRING SERVO TENSIONER

SHOW TENSIONER VALUE