product

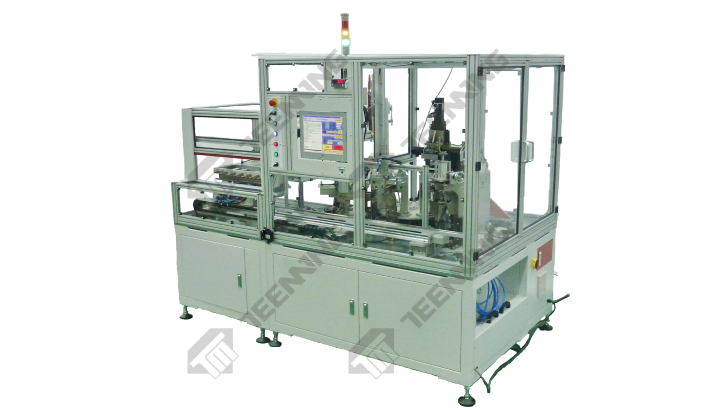

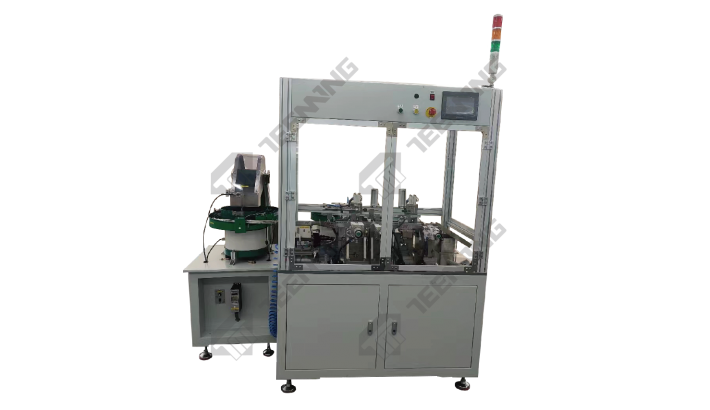

AIP-28 AUTO PIN INSERTING MACHINE

AIP-28 High-Speed Automatic Pin Insertion Machine — Precision, Efficiency, and Smart Automation

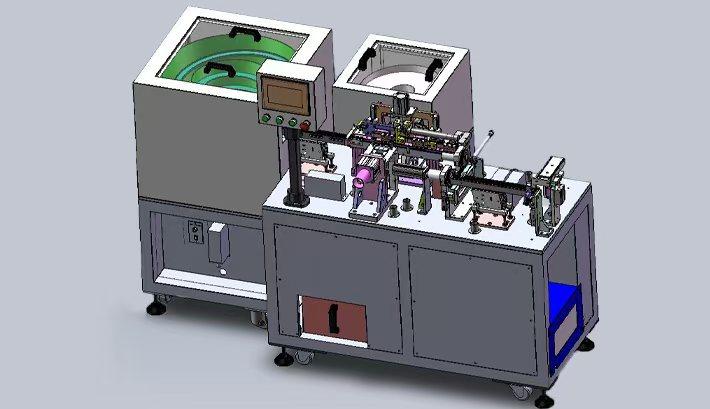

The AIP-28 is purpose-built for high-speed, high-precision pin insertion, combining rapid production cycles, flexible tooling, and stable quality control to meet the demands of modern manufacturing. Its modular design allows for quick jig changes, enabling seamless adaptation to different product types and significantly reducing line-switching time.

This machine supports a wide range of pin formats—including round, square, and flat pins—with both vertical and L-shaped insertion capabilities. Each cycle can insert up to 20 pins, achieving speeds of up to 60 pieces per minute, making it ideal for high-volume production. The fully automated workflow integrates feeding, insertion, pressing, cutting, and unloading, minimizing manual labor while ensuring consistent output.

Optional modules such as a heating unit enhance material compatibility and insertion stability, while the insertion force monitoring system ensures reliability for high-spec applications like automotive electronics and precision components. Paired with a vibratory bowl feeder and auto-counting features, the AIP-28 further boosts productivity and traceability.

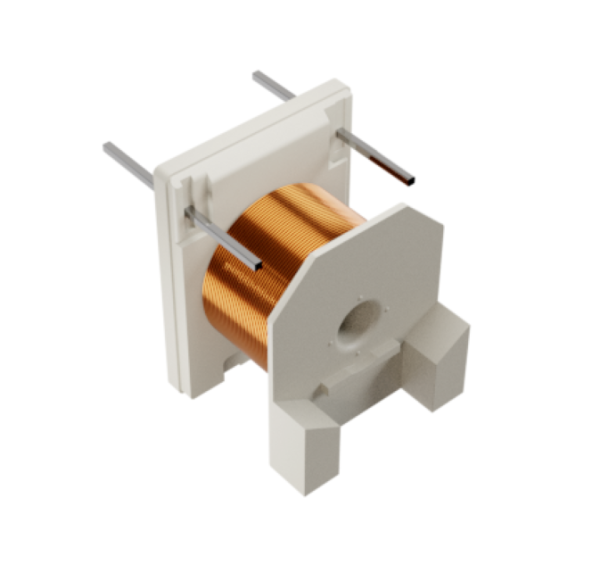

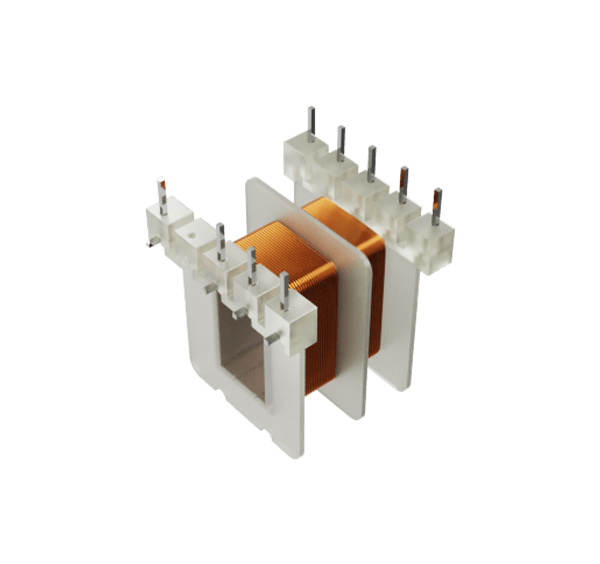

Whether you’re manufacturing connectors, coils, relays, or other electronic components, the AIP-28 delivers a stable, efficient, and scalable solution—your ideal partner on the path to smart manufacturing.

The AIP-28 is purpose-built for high-speed, high-precision pin insertion, combining rapid production cycles, flexible tooling, and stable quality control to meet the demands of modern manufacturing. Its modular design allows for quick jig changes, enabling seamless adaptation to different product types and significantly reducing line-switching time.

This machine supports a wide range of pin formats—including round, square, and flat pins—with both vertical and L-shaped insertion capabilities. Each cycle can insert up to 20 pins, achieving speeds of up to 60 pieces per minute, making it ideal for high-volume production. The fully automated workflow integrates feeding, insertion, pressing, cutting, and unloading, minimizing manual labor while ensuring consistent output.

Optional modules such as a heating unit enhance material compatibility and insertion stability, while the insertion force monitoring system ensures reliability for high-spec applications like automotive electronics and precision components. Paired with a vibratory bowl feeder and auto-counting features, the AIP-28 further boosts productivity and traceability.

Whether you’re manufacturing connectors, coils, relays, or other electronic components, the AIP-28 delivers a stable, efficient, and scalable solution—your ideal partner on the path to smart manufacturing.

FEATURES

- Change tooling easily

- Pre-heating

- High effective

- Quality conformity

- Manual loading

- Automatic insertion

- Automatic swaging

- Automatic unloading

PROCESS

Bowl feeder

↓

Bobbin load to shooter

↓

Make trace on pin then insert into bobbin

↓

Cut pin

↓

Unload inserted pin bobbin

↓

Bobbin load to shooter

↓

Make trace on pin then insert into bobbin

↓

Cut pin

↓

Unload inserted pin bobbin

SPECIFICATION

| Power source | AC 380 50 HZ 3 Phase |

| Machine dimension | 660(L) X 1300(W) X 2100(H) mm |

| Weight | 180KGS |

| Air pressure | 6KG/ c㎡ |

| Pin diameter | 0.3-1.0 mm |

| Pin length | 35 mm |

| Cycle time | 40-60 pcs/min |

| Pin type | Round square and flat pins |

| Total pins | 20 pins |

| Insertion ability | Straight and L pin |

| Option | 1.Bowl feeder 2.Heating from loading shoot |