product

HOME

Product

AUTO COIL WINDING MACHINE

Tags:

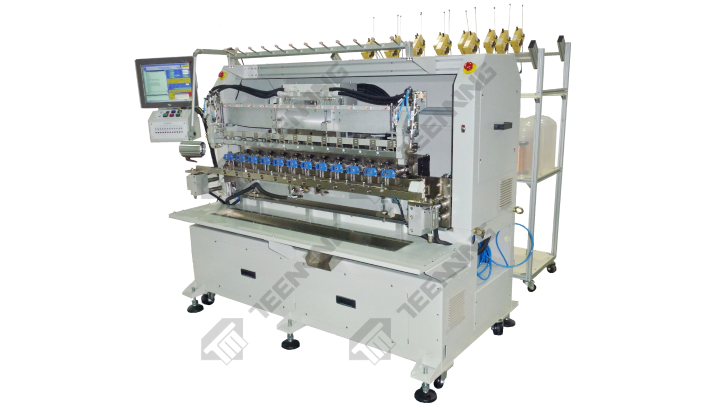

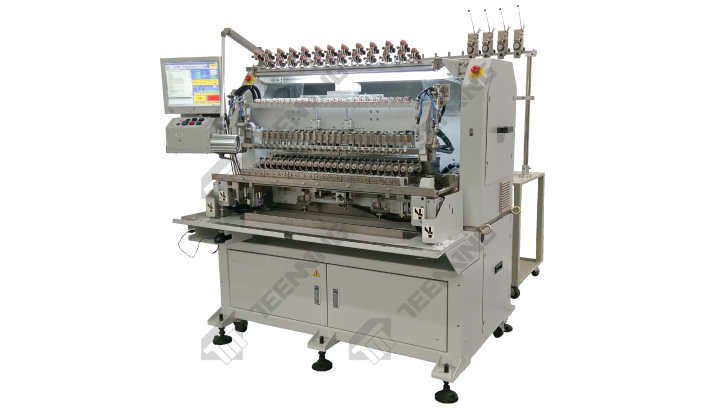

AUTO COIL WINDING MACHINE

A coil winding machine is a device used to create coils that are used in various electronic applications. These machines are typically used in the manufacturing of relay, solenoid, transformers, inductors, and other electrical components. Teeming's winding machine can add cutter, twister, servo tensioner suit for your product. The coil winding machine controller is PAC controller, it can control the winding lineand connect with auto line to reduce cost and increase production capacity.

Related Products-Auto Winding Machines

TM-1302_2 SPINDLE AUTO WINDING

Between 2 spindle pitch 130mm

TM-5004_4 SPINDLE AUTO WINDING

Between 2 spindle pitch 50mm

TM-8006_6 SPINDLE AUTO WINDING

Between 2 spindle pitch 80mm

TM-1006_6 SPINDLE AUTO WINDING

Between 2 spindle pitch 100mm

TM-5008_8 SPINDLE AUTO WINDING

Between 2 spindle pitch 50mm

TM-8008_8 SPINDLE AUTO WINDING

Between 2 spindle pitch 80mm

TM-1008_8 SPINDLE AUTO WINDING

Between 2 spindle pitch 100mm

TM-1308_8 SPINDLE AUTO WINDING

Between 2 spindle pitch 130mm

TM-3612_12 SPINDLE AUTO WINDING

Between 2 spindle pitch 36mm

TM-5012_12 SPINDLE AUTO WINDING

Between 2 spindle pitch 50mm

TM-8012_12 SPINDLE AUTO WINDING

Between 2 spindle pitch 80mm

TM-1012_12 SPINDLE AUTO WINDING

Between 2 spindle pitch 100mm

TM-3016_16 SPINDLE AUTO WINDING

Between 2 spindle pitch 30mm

TM-5016_16 SPINDLE AUTO WINDING

Between 2 spindle pitch 50mm

TM-5020_20 SPINDLE AUTO WINDING

Between 2 spindle pitch 50mm

TM-3624_24 SPINDLE AUTO WINDING

Between 2 spindle pitch 36mm

TM-3632_32 SPINDLE AUTO WINDING

Between 2 spindle pitch 36mm

TM-4032_32 SPINDLE AUTO WINDING

Between 2 spindle pitch 40mm

Process - Auto Coil Winding Machine

1. Load the bobbin onto the spindle of the automatic coil winding machine.

Secure the bobbin in place to prevent any movement during the coil winding process. The coil winding tooling serves as the foundation for the wire coils.

2.Start the automatic coil winding machine to initiate the coil winding process. The coil winding machine will rotate the bobbin and guide the wire onto it according to the specified parameters.

3.End winding, once the desired number of turns or layers is reached, secure the ending end of the wire to the bobbin.

4.Carefully remove the fully wound bobbin from the spindle. Take care to avoid any damage to the wound coils during the unloading process.

FAQs about Auto Winding Machines

Q1: What types of coil winding machines do you offer?

A1: This model is a fully automatic coil winding machine, capable of operating independently or integrating with automated production lines to increase productivity and reduce labor costs.Learn more:What Is an Electric Motor Coil Winding Machine? A Complete Guide to Motor Winding Types.