What Is Winding Machines Used For?4 Available Features You Need to Know !

Winding machines are a key piece of equipment for the automated production of metal coils. This guide explains how and why these machines are used and the available features.At Teeming Machinery, we provide a wide range of equipment for different industries. These pieces of equipment can be used to speed up and maximize the efficiency of processes in various businesses. One of the most popular types of equipment we offer are winding machines. In this article, we’ll explore what winding machines are, how they are used and the key features which could make them ideal for your business model.

What Is A Winding Machine?

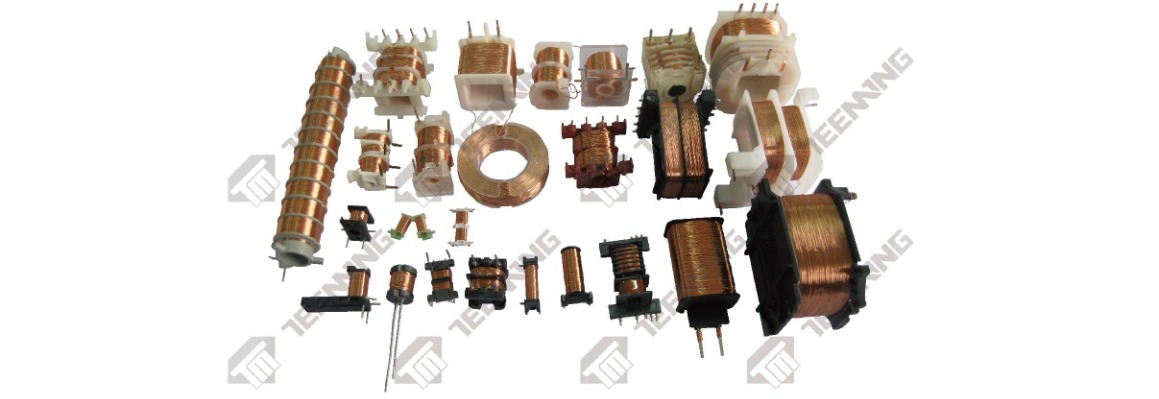

A winding machine is a piece of equipment that can be used for wrapping different types of metal coils for various purposes. Some examples include:

View more related types:

- Auto Coil Winding Machine

- Automatic Motor Winding Machine

- Relay Automatic Coil Winding Machine

- Solenoid & Valve Coil Winding Machine

- Transformer Coil Winding Machine

These metal coils can be wound around different pieces of equipment so that they can be used in a wide range of purposes. Winding machines are a common part of the manufacturing process that is key to creating mechanical equipment.

They are most commonly used for creating tight coils such as an ignition coil. An ignition coil also referred to as a spark coil is part of the ignition system in a vehicle. This transformers the voltage from the battery into thousands of volts. In modern vehicles, much smaller cars are used with one coil required for each spark plug. As such, countless coils are used for the engine of just one car. This is one of the reasons why it has become increasingly important to ensure that these parts can be created and produced at a far faster rate. That’s exactly what automated winding machines do and it’s just one example.

Winding machines come in various different sizes and designs. For instance, there are winding machines that can wind one metal coil at a time as well as machines that can wind multiple coils.

Some of the types of metal coil winding machines include:

-

Single-axis winding machine

-

Multi-axis winding machine

-

Winding coating machine

-

Production line

Functions Of A Winding Machine

The main function of a winding machine is - as you might have guessed - winding.

Winding refers to the process of winding coils so that they can be used for a specific part or purpose in a larger piece of equipment such as a car engine.

Modern winding machines can wind coils at a speeds ranging from 2000 to 6000 RPM. It is important to choose the right winding machine for your business process.

Aside from the primary function of a winding machine, there are also auxiliary functions to be aware of. These include:

-

Wire twister(wire diameter under 0.05mm)

-

Automatic loading & unloading(bobbin width under 22mm)

-

Cutter (wire diameter: over 0.28mm)

-

Knife (wire diameter: over 0.15mm)

-

Electrical tensioner

-

Servo tensioner

Different Types Of Features Of A Winding Machine

Winding machines can have a variety of different features. This will often depend on the type of winding machine that you choose to use in your business.

Wire Break Alarm

- Spring servo tensioner

- Simple servo tensioner

- Pneumatic servo tensioner

- Electronic tensioner

- Magnetic tensioner

These tensioners can connect with winder, if wire break, machine will alarm, the user can know which spindle’s wire is braked quickly.

Besides, wire break alarm, Teeming’ machine is matched with the cylinder and sensor, and the program can know which cylinder is not moving, or the machine is stopped due to the failure of the sensor to detect it.

Actuated Knife Cut-Off

A winding machine can have a knife blade. This is used to cut wire. The knife can be actuated through the use of an electrical or pneumatic actuator depending on the type of machine.

A teeming cutter can cut enameled copper wire of more than 0.15mm, if it is less than 0.15mm, it is recommended to use a knife.

Automatic Or Manual Role Change

Teeming’s product can use for many different kinds of coil, when this coil has been finish produced, the coil of winding machine tooling will need to be changed. Teeming winding machines ensures that this is a changed process.

When changed to other coil, the first thing is change to manual mode to check the tooling position whether is okay, if okay, machine can start produced.Then Teeming modern automated winding machines are capable of delivering both high speed core loading and tooling changes quickly.

Teeming Winding Machine: Types And Benefits

We have more than 30 years of experience providing automated coil solutions that businesses need as part of their production line. Our winding machines are tried, tested and proven to deliver the results that businesses require. We started producing winding machines in 2007. Since then the machines we have sold have won numerous awards. For instance, our Needle Winder won the Taiwan Excellence Award from the Taiwan Government in 2015. We are committed to constantly taking steps to improve our products so that we can guarantee businesses can order the best winding machines for their production line.

At Teeming Machinery we offer three main types of winding machines with variations that you can choose for your business. The right type will depend on the type of material that you are winding as well as output and production requirements.

Auto Winding Machine

We have auto winding machines with between 4 and 32 spindles depending on your business size and requirements. These are suitable for different types of small bobbins so you can easily customize the jig. The machine can also be used to perform precise layer winding. You can also take advantage of automatic solutions to speed up your production process, increase your capacity and reduce the number of employees required. These systems also boast low levels of required maintenance, ensuring that they will continue to function without downtime.

Motor Winding Machine

Our motor winding machines provide significant benefits including accurate coil wire positioning. This ensures that the machine operates at a high speed and provides the rapid standards of production you require. You can also use high speed needle winding capabilities to maximize your efficiency standards. Similar to our auto winding machines, the jig can be adjusted and changed easily when required.

Single Winding Machine

We also stock 4 single winding machines which will be ideal for smaller businesses and companies with a lower number of production requirements. These systems are easy to control and you can quickly set up the program that you need. As such, you will have no problem ensuring that your production process is firing on all cylinders.

We hope this provides all the information you need about the winding machines and the different types that we offer. If you need more details or you don’t know which type of machine is right for your company, please do not hesitate to contact us today. We will be happy to assist you further and ensure that you get the best machine to match your business requirements.

New Product Recommendation: TM4032 Winding Machine

TM4032 - High-Speed Winding Machine

The TM4032 Winding Machine features a 40mm spacing and 32 shafts, allowing it to produce up to 32 products simultaneously. With a maximum speed of 18,000 rpm, this machine is designed for high-efficiency winding. The dual-motor control system optimizes the winding rotating shaft, extending belt lifespan and ensuring high stability in winding quality.

To enhance production flexibility, the TM4032 Winding Machine offers optional add-ons such as:

- Stranding machine for multi-wire winding

- Tape wrapping machine for insulation and reinforcement

- Scissors mechanism for automatic wire cutting

- Servo tensioner for precise tension control

Non-Stacking Wire Mechanism

The Non-Stacking Wire Mechanism effectively eliminates pin-start corner stacking issues. It ensures that the winding at the start and end corners remains consistent, preventing soldering difficulties at the rear end. This feature guarantees that PIN corner welding heights are uniform, improving the overall reliability of the finished product.

Advanced Tensioner Control System

The tensioner control system is integrated with the winding machine, allowing for precise tension consistency and multi-stage tension adjustment. It is also MES-compatible, enabling real-time monitoring of the tensioner status. This proactive system helps detect issues immediately, reducing downtime and minimizing product scrap rates.

With its high-speed performance, precision control, and advanced automation features, the TM4032 Winding Machine is the ideal solution for manufacturers seeking efficient and high-quality winding production.

Winding Machine FAQs

Q1: What is a coil winding machine?

A1: A coil winding machine is an automated or semi-automated device used to wind wire (typically copper or aluminum) evenly onto a core, bobbin, or frame. It is commonly used in the production of transformers, motors, inductors, solenoids, and other electronic or electromechanical components.Q2: How to wind a wire coil?

A2: The wire coil winding process generally involves:● Setting winding parameters (number of turns, tension, speed, etc.)

● Loading the wire onto the tensioner

● Starting the machine to automatically wind the wire according to the preset direction and number of layers

● Completing the process with cutting, lead-out, soldering, or taping as needed

Q3: What is the cost of winding a coil?

A3: The cost depends on factors such as wire material, wire gauge, winding complexity, machine type, labor, and production volume. In general, automatic coil winding machines significantly reduce labor costs and improve yield, making them more cost-effective for medium- to high-volume production.Q4: What types of wire can coil winding machines handle?

A4:Coil winding machines can process a wide variety of wires, including:● Enamel-coated copper wire

● Insulated aluminum wire

● Multi-stranded wire

● Ultra-fine wire The supported wire types depend on the machine’s tension system and precision level.

Q5: How to maintain a coil winding machine?

A5: Regular maintenance includes:● Cleaning machine components and moving parts

● Checking wire tensioners and wire guides

● Testing the responsiveness of the control system

● Lubricating and replacing wear parts (e.g., belts, linear rails) Routine maintenance ensures the machine’s stability and extends its lifespan.