RELAY-AUTOMATIC COIL WINDING MACHINE

Learn more: What Is Winding Machines Used For?4 Available Features You Need to Know !

Related Products-RELAY-AUTOMATIC COIL WINDING MACHINE

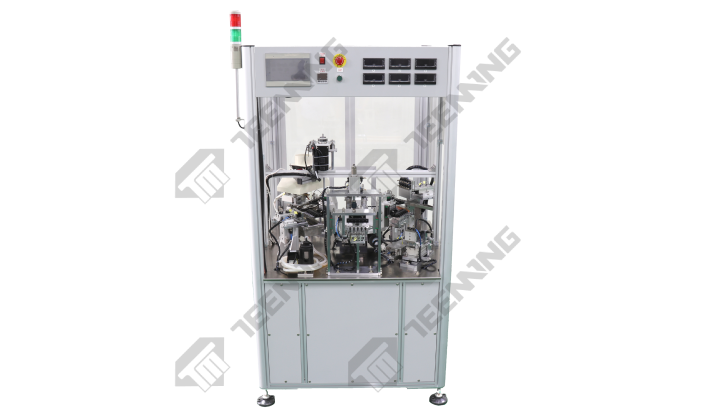

AIP-28 AUTO PIN INSERTING MACHINE

(1) The body is inclined to 30 degrees, easy to feed and withdraw materials, and the vibration barrel for feeding materials is optional.

(2) large versatility, only need to replace special components, can change the type in a short time.

(3) Round PIN, corner PIN, flat PIN, are applicable.

(4) Up to 20 pins can be inserted at the same time.

(5) PIN length, groove position, easy to adjust.

(6) When the wire is used up or broken, it can automatically detect the stop.

(7) Outside the linear PIN press, it can also be bent PIN 0~90 degrees.

(8) Can be used with the production line according to the user's requirements and design

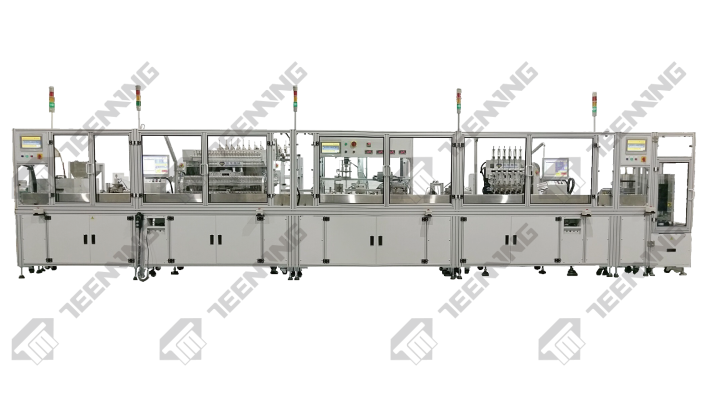

TM-5016_16 SPINDLE AUTO WINDING

Between 2 spindle pitch 50mm

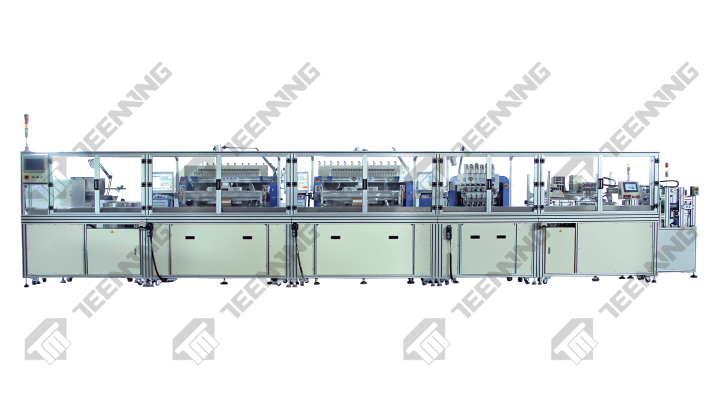

16 SPINDLE AUTO WINDING+TAPING

Between 2 spindle pitch 50mm

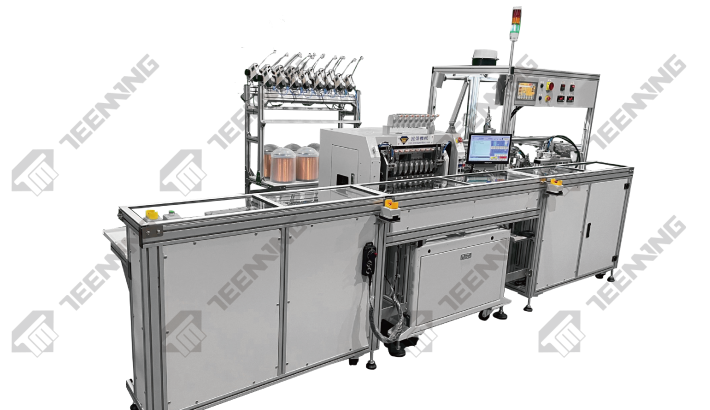

TM-5008-08-TP_8 SPINDLE AUTO TAPING

Between 2 spindle pitch 50mm

TM-3612-12-TP_12 SPINDLE AUTO TAPING

Between 2 spindle pitch 36mm

Process - Relay-automatic Coil Winding Machine

1. Load the bobbin onto the spindle of the relay-automatic coil winding machine. Secure the bobbin in place to prevent any movement during the winding process. The bobbin serves as the foundation for the wire coils.

2.Start the relay-automatic coil winding machine to initiate the winding process. The machine will rotate the bobbin and guide the wire onto it according to the specified parameters.

3.End winding, once the desired number of turns or layers is reached, secure the ending end of the wire to the bobbin.

4.Carefully remove the fully wound bobbin from the spindle. Take care to avoid any damage to the wound coils during the unloading process.