product

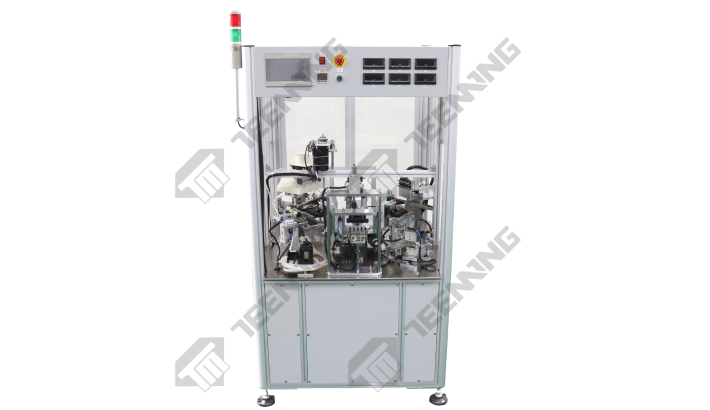

10 STATION SOLDERING

A soldering machine is a specialized device used in electronics manufacturing and various other industries for the process of soldering.

The soldering machine is equipped with a heating element, the heating element rapidly heats the soldering tip to the desired temperature for melting the solder.

Soldering machines come with precise temperature control to ensure that the soldering tip reaches and maintains the optimal temperature for the specific soldering task. Different soldering applications require different temperatures to achieve the best results.

Soldering machines often have a digital display to show the set and actual temperatures, as well as control to adjust the temperature and other settings.

The soldering machine is equipped with a heating element, the heating element rapidly heats the soldering tip to the desired temperature for melting the solder.

Soldering machines come with precise temperature control to ensure that the soldering tip reaches and maintains the optimal temperature for the specific soldering task. Different soldering applications require different temperatures to achieve the best results.

Soldering machines often have a digital display to show the set and actual temperatures, as well as control to adjust the temperature and other settings.

FEATURES

- Automatic 10 station

- Multi-station design

- Suitable for small quantity and different type of coil

- Customize jig and change it easy

- Automatic dip solder

- It can set volume of dip flux

- Automatic detect height of dip solder

- Function of displacement

- Dip cup up and down by servo motor

- It can set soldering time

- Promote effectiveness and increase capacity

PROCESS

Put coil to the fixture

↓

Fluxing

↓

Soldering 1

↓

Bending 1

↓

Turn

↓

Fluxing

↓

Soldering 2

↓

Bending 2

↓

DCR test & NG

↓

OK unload to conveyer

Learn more: What Is a Soldering Machine Used For?A Full Guide To Know How Does It Work!

↓

Fluxing

↓

Soldering 1

↓

Bending 1

↓

Turn

↓

Fluxing

↓

Soldering 2

↓

Bending 2

↓

DCR test & NG

↓

OK unload to conveyer

Learn more: What Is a Soldering Machine Used For?A Full Guide To Know How Does It Work!

SPECIFICATION

| Flux control system | AC servo motor |

| Solder control system | AC servo motor |

| Load bobbin Q'TY | 4pcs |

| Load bobbin distance | 50mm |

| Working table height | 1050+/-50mm-adjustable |

| Temperature | 400±10 °C |

| Production capacity | 164 parts / hour |

| Max. speed of slider | 1500 RPM |

| Spindle way accuracy | +/-0.02mm |

| Power Source | 220V 1phase |

| Consumed power | 4KW |

| Air Pressure Supply Required | 0.8 MPa |

| Machine Dimension | 2500(L)x1650(W)x180(H)mm |

| Machine weight | 730KGS |

Flux Mixing:

| S.G. measurement range | 0.800~0.900(standard)<1.00 |

| S.G. accuracy | ±0.003 |

| S.G. control | Temperature compensation(converted to value at 20°C) |

| Liquid level control range | About 5mm between high and low limits |

| Liquid temperature | 10-50°C |

| Measurement range | ±2.0°C |

| Life meter | Digital indication of flux contamination indicatied in ppm (0~50x10ppm) |

| Liquid supply method | Automatic pump supply method (head 1m.500ml/min) |

| Liquid exhaustion | Warned of automatically by buzzer LED(red),relay output(NO contact) |

| Employed tank | 180L can(directly usable) |

| External output | 0-1V(DC) |

| Sensor cord | 3m |

| Input/output tube | 6m |

| Wetted section material | PVC,Stainless steel,Viton,PE,PP,Fluorocarbon,PA,Polyurethane,EPT |

| Operating surrounding temperature | 10~50°C |

| Power supply | 100,115,200,220,240VAC 50/60HZ |

| Power consumption | 35VA rating |

| Fuse | 2A |

| Weight | 11kg |

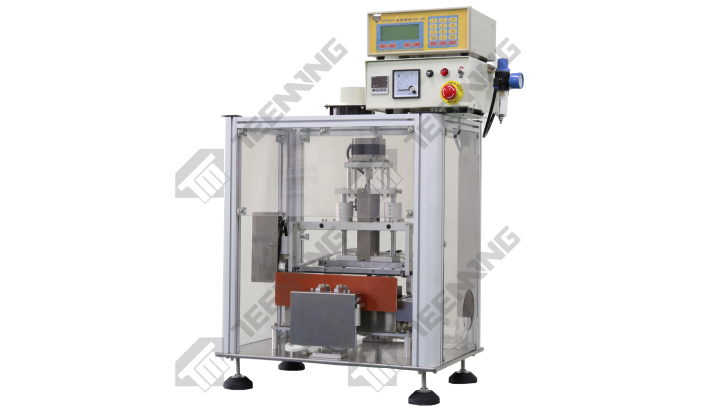

Related Products

ETS-2MT CNC IN-LINE SOLDERING

Angled Soldering Machine

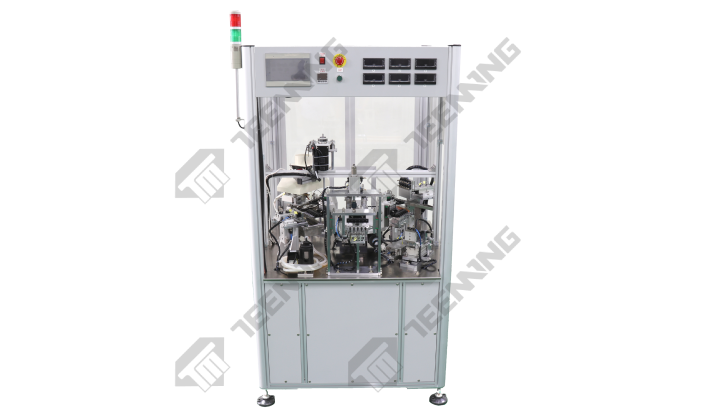

ETS-2MTFMS CNC IN-LINE SOLDERING

Angled Soldering Machine