SOLENOID WINDING MACHINES

Teeming’s Solenoid Winding Machine offers various customizable options, including a cutter, twister, tape applicator, and a servo tensioner, to meet different production requirements. The machine is equipped with a PAC controller, which enables precise winding control and seamless integration with automated production lines. This automation not only enhances production efficiency but also reduces costs, making it an ideal solution for high-volume manufacturing.

With advanced features and high precision, Teeming’s Solenoid Winding Machine helps manufacturers achieve superior winding quality and increased production capacity.

Learn more: What Is Winding Machines Used For?4 Available Features You Need to Know !

Related Products-SOLENOID WINDING MACHINES

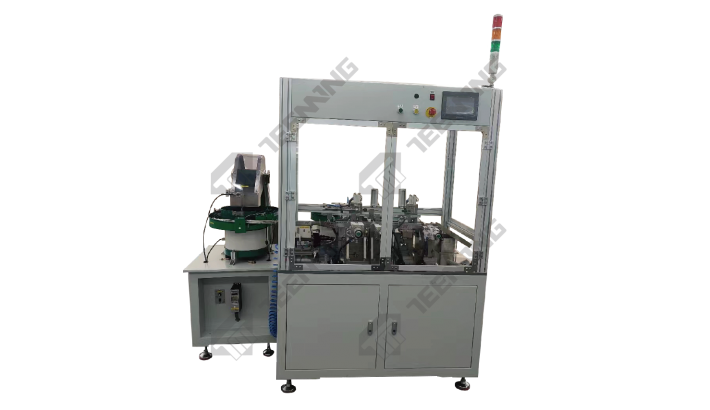

TM-8012_12 SPINDLE AUTO WINDING

Between 2 spindle pitch 80mm

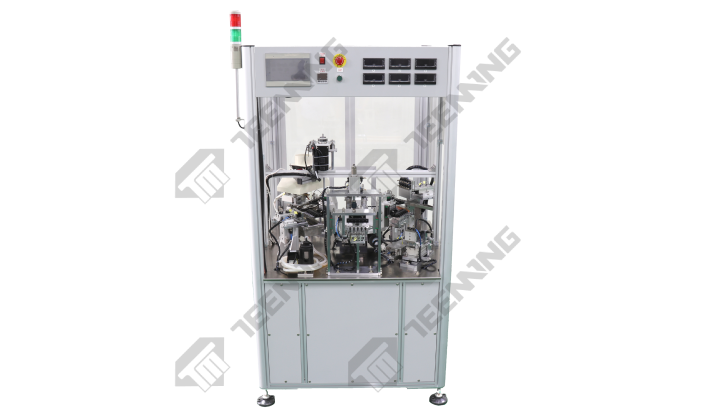

TM-5016_16 SPINDLE AUTO WINDING

Between 2 spindle pitch 50mm

Process - Solenoid Valve - Automatic Coil Winding Machine

1. Load the bobbin onto the spindle of the solenoid winding machine. Secure the bobbin in place to prevent any movement during the winding process. The bobbin serves as the foundation for the wire coils.

2.Start the solenoid winding machine to initiate the winding process. The machine will rotate the bobbin and guide the wire onto it according to the specified parameters.

3.End winding, once the desired number of turns or layers is reached, secure the ending end of the wire to the bobbin.

4.Carefully remove the fully wound bobbin from the spindle. Take care to avoid any damage to the wound coils during the unloading process.

FAQs about SOLENOID WINDING MACHINES

Q1. What are the differences between solenoid winding machines and valve winding machines?

A1. Solenoid winding machines are specifically designed for winding solenoid coils, while valve winding machines are designed for winding coils for hydraulic and pneumatic valves.Learn More:What Is Winding Machines Used For?4 Available Features You Need to Know !

Q2. How do I choose a suitable solenoid or valve winding machine model?

A2. You can share the coil drawing, winding specifications, and cycle time you require, and we will recommend the best machine model for your needsView more coil related types: