product

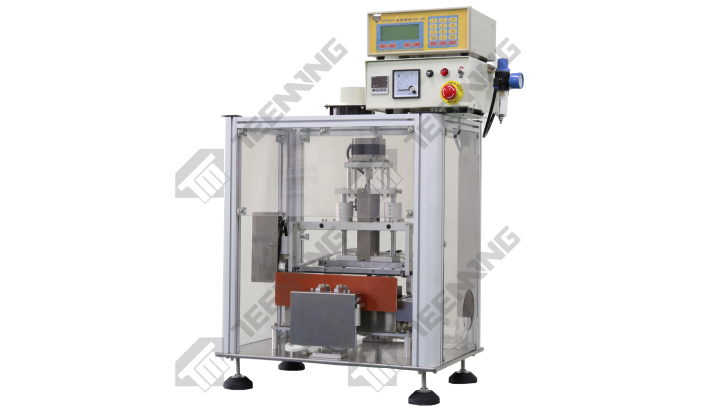

2MTFA-LINEAR SOLDERING MACHINE

A soldering machine is a specialized device widely used in electronics manufacturing and other industries for soldering tasks.

It features a heating element that quickly heats the soldering tip to the required temperature for melting solder. With precise temperature control, it ensures stable and reliable soldering performance. Different soldering applications require different temperatures to achieve optimal results.

It features a heating element that quickly heats the soldering tip to the required temperature for melting solder. With precise temperature control, it ensures stable and reliable soldering performance. Different soldering applications require different temperatures to achieve optimal results.

FEATURES

- Suitable for small quantity and different type of coil

- Customize jig and change it easy

- Automatic dip solder

- It can set volume of dip flux

- Automatic detect height of dip solder

- Function of displacement

- Dip cup up and down by servo motor

- It can set soldering time

- Promote effectiveness and increase capacity

PROCESS

Put coil to the fixture

↓

Fluxing

↓

Soldering 1

↓

Turn

↓

Fluxing

↓

Soldering 2

↓

Bending 2

↓

DCR test & NG

↓

OK unload to conveyer

↓

Fluxing

↓

Soldering 1

↓

Turn

↓

Fluxing

↓

Soldering 2

↓

Bending 2

↓

DCR test & NG

↓

OK unload to conveyer

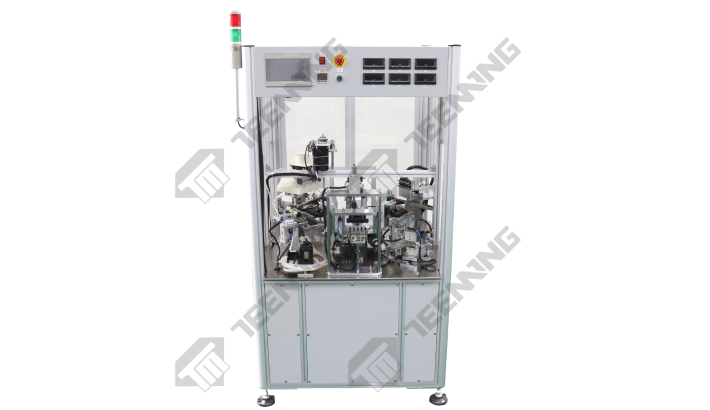

SPECIFICATION

| Item No. | ETS-2MTFA |

| Description | ANGLE SOLDER,MOVE,BY SERVO MOTOR |

| Soldering way | Jig angle turn |

| Power source | AC220V 3000W |

| Machine dimension | 120(L) x 110(W) x 180(H) cm |

| Weight | 400KGS |

| Air pressure | 6KGS/cm² |

| Inner pot size | 295(L) x 105(W) x 45(H) mm |

| Cycle time | 10-20 pcs / 10-12 sec |

| Pot Material | Titanium |

| Temperature | 600 ℃ MAX. |

| Dip cup up/down distance | 310(L) x 76(W) x 40(H)mm |

| Suitable | Anycoil |

2. Feed solder automatically

3. Leave solder dross after dip solder

4. Servo motor control , dip cup up down

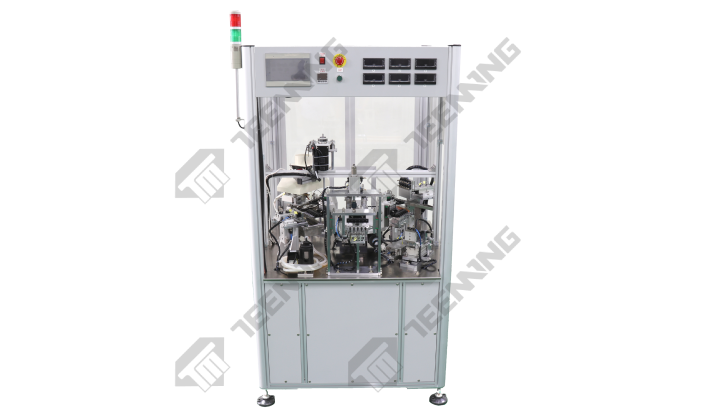

Related Products

ETS-2MT CNC IN-LINE SOLDERING

Angled Soldering Machine

ETS-2MTFMS CNC IN-LINE SOLDERING

Angled Soldering Machine